NEWS BFM

05.09.2025

BFM goes on to Celebrates “50 Years of Excellence” at the K 2025 Exhibition in Germany!

This year is truly special for BFM, which celebrates its 50th anniversary of uninterrupted excellence in the sector.

2025 marks indeed , the fiftieth anniversary of BFM, the company from Solbiate Olona (Varese), specialized in the production of flexographic printing machines, automatic Take -off units and winders for blown film extrusion lines.

Founded in 1975, BFM has become a reference name for "Made in Italy", thanks to the quality of its solutions and its constant ability to innovate, always maintaining a strong bond with our customers.

The company has always had a strong international footprint: “We are present all over the world, with agents and customers on all continents, from America to Asia, with a strong presence also in Africa.”

“Having always been a medium-sized company has had a positive impact,” says Simona Colombo.Sales and Marketing Manager “This has allowed us to adopt a proactive approach and to remain close to customers, guaranteeing technologically advanced, reliable and rapid solutions.

Our agility has allowed us to develop customized solutions based on customer needs, a flexibility that has distinguished us from the beginning and that continues to be so in a market that, as is known, has changed radically over the years.”

For the first time , after many years, will we will be happy to partecipate at the Exhbition with:

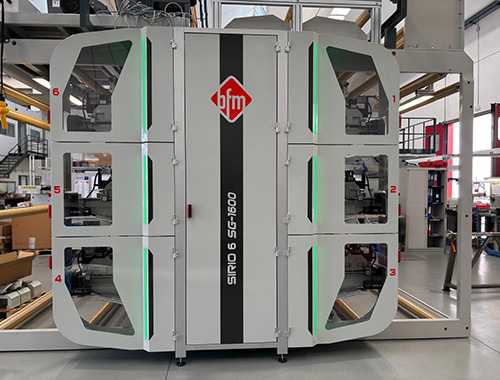

An In – Line Flexo Printer 6 Col – 1600 mm ,a novelty in our range of Stack type flexographic printing machines.

Our SIRIO SG line is a versatile printing unit, allowing it to be installed in-line with blown film extruder or offline, with an unwinder and rewinder, while maintaining the same printing unit body.

The unit we are presenting at K2025 is the in-line version with extruder, 6 colors, 1600 mm wide.

Its main feature is the perfect communication with the extrusion systems thanks to the "Bosch Rexroth Motion" system and our on-board control systems, such as material anomaly detection and our "moving " automatic pre-setting system.

“SIRIO SG INLINE” presents itself with an innovative look and presents some great innovations among its technical features, including quicker job changeover in the machine, the printing set point already tested on the S-PLUS models and even greater versatility regarding communication with the extrusion lines and/or bag Makers .

All obviously with a single goal , that one of reducing production waste as much as possible.

Finally, "SIRIO SG INLINE" was also produced in "extralarge" widths such as 2600 and 2800 mm, with repeat lenghts ranging up to 1200 mm

The automation platform of these Presses has been designed using the proven application experience of Bosch Rexoth, , the industry leader in the automation of printing and converting machines

The use of Brushless motors with CtrlX plastform , which moves the color group composed of counter-roller-clichè-anilox, guarantees great dimensional compactness and the right printing precision . The use of the IndraDrive digital series guarantees constant position synchronism between the different printing elements, with consequent register maintenance both at high speeds and during acceleration and deceleration. Initial registration is very quick and can also be done when the machine is stopped, significantly reducing energy and material waste. Today , even more flexible through the adoption of a full electronic positioning system., each color group can be moved longitudinally in a completely independent way thanks to the adoption of Indradrive servo axes and MS2N motors equipped with absolute multiturn encoder: the results are: a most accurate set point, the management of storable recipes, the reduced reconfiguration times . In addition to the innovations that BFM will present during the exhibition, the staff will reveal other important features related to other lines such as the specific Printing lines for industrial bags with gusseting and embossing units the so called “FFS Lines” , the 6/8 Col Gearless central drum Flexo Presses and finally the Stack type Presses Roll to roll . As said apart of Flexo Presses , another BFM focus is the production of blown film winders, offering the option of replacing an old winder on an existing extrusion line with a new one. Our systems are very easy to install in-line with any blown film extruder of any brand, improving the production of wounded plastic film reels. Our winders are able to operate in a sustainable way respecting enviromental isuues and are designed with a series of safety features and equipped with a Plc Safe to prevent workplace accidents. We look forward to welcoming you to our booth Hall 17 Stand C 05 , where our team will be available to show You the new machine's features and discuss the best solutions for your business. We conclude by sincerely thanking our long-standing customers, who have trusted us on our growth path for years, and extending a warm welcome to all new visitors who will come to visit us.

2025 marks indeed , the fiftieth anniversary of BFM, the company from Solbiate Olona (Varese), specialized in the production of flexographic printing machines, automatic Take -off units and winders for blown film extrusion lines.

Founded in 1975, BFM has become a reference name for "Made in Italy", thanks to the quality of its solutions and its constant ability to innovate, always maintaining a strong bond with our customers.

The company has always had a strong international footprint: “We are present all over the world, with agents and customers on all continents, from America to Asia, with a strong presence also in Africa.”

“Having always been a medium-sized company has had a positive impact,” says Simona Colombo.Sales and Marketing Manager “This has allowed us to adopt a proactive approach and to remain close to customers, guaranteeing technologically advanced, reliable and rapid solutions.

Our agility has allowed us to develop customized solutions based on customer needs, a flexibility that has distinguished us from the beginning and that continues to be so in a market that, as is known, has changed radically over the years.”

For the first time , after many years, will we will be happy to partecipate at the Exhbition with:

An In – Line Flexo Printer 6 Col – 1600 mm ,a novelty in our range of Stack type flexographic printing machines.

Our SIRIO SG line is a versatile printing unit, allowing it to be installed in-line with blown film extruder or offline, with an unwinder and rewinder, while maintaining the same printing unit body.

The unit we are presenting at K2025 is the in-line version with extruder, 6 colors, 1600 mm wide.

Its main feature is the perfect communication with the extrusion systems thanks to the "Bosch Rexroth Motion" system and our on-board control systems, such as material anomaly detection and our "moving " automatic pre-setting system.

“SIRIO SG INLINE” presents itself with an innovative look and presents some great innovations among its technical features, including quicker job changeover in the machine, the printing set point already tested on the S-PLUS models and even greater versatility regarding communication with the extrusion lines and/or bag Makers .

All obviously with a single goal , that one of reducing production waste as much as possible.

Finally, "SIRIO SG INLINE" was also produced in "extralarge" widths such as 2600 and 2800 mm, with repeat lenghts ranging up to 1200 mm

The automation platform of these Presses has been designed using the proven application experience of Bosch Rexoth, , the industry leader in the automation of printing and converting machines

The use of Brushless motors with CtrlX plastform , which moves the color group composed of counter-roller-clichè-anilox, guarantees great dimensional compactness and the right printing precision . The use of the IndraDrive digital series guarantees constant position synchronism between the different printing elements, with consequent register maintenance both at high speeds and during acceleration and deceleration. Initial registration is very quick and can also be done when the machine is stopped, significantly reducing energy and material waste. Today , even more flexible through the adoption of a full electronic positioning system., each color group can be moved longitudinally in a completely independent way thanks to the adoption of Indradrive servo axes and MS2N motors equipped with absolute multiturn encoder: the results are: a most accurate set point, the management of storable recipes, the reduced reconfiguration times . In addition to the innovations that BFM will present during the exhibition, the staff will reveal other important features related to other lines such as the specific Printing lines for industrial bags with gusseting and embossing units the so called “FFS Lines” , the 6/8 Col Gearless central drum Flexo Presses and finally the Stack type Presses Roll to roll . As said apart of Flexo Presses , another BFM focus is the production of blown film winders, offering the option of replacing an old winder on an existing extrusion line with a new one. Our systems are very easy to install in-line with any blown film extruder of any brand, improving the production of wounded plastic film reels. Our winders are able to operate in a sustainable way respecting enviromental isuues and are designed with a series of safety features and equipped with a Plc Safe to prevent workplace accidents. We look forward to welcoming you to our booth Hall 17 Stand C 05 , where our team will be available to show You the new machine's features and discuss the best solutions for your business. We conclude by sincerely thanking our long-standing customers, who have trusted us on our growth path for years, and extending a warm welcome to all new visitors who will come to visit us.