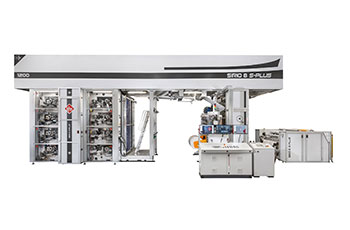

SIRIO S PLUS 6/8 COLORS REEL TO REEL

Sirio Model S Plus are 6/8 color Stack type machines, designed for printing on different plastic materials for the packaging market but also suitable for paper materials, in line with the extruder or from reel to reel.

They are normally developed for medium-run jobs with printing jobs one side 6 + 0 and " front /reverse " 3+ 3-4 + 2-5 + 1 for the 6 col. , 8 + 0 and "front / reverse" 4 + 4-3 + 5-2 + 6 for the 8 Col.

The mechanical structure is configurated with all printing groups perfectly horizontal and all machines are prepared for printing with solvent or water-based inks. Max mechanical speed is around 250 mt/min.

The mechanical transmission is made trough a torque motor for each printing unit, to ensure better precision and to set electrically the longitudinal register at 360 °

The use of digital drives ensures constant position synchronism between the different printing elements, with consequent maintenance of the register both at high speeds and during acceleration and deceleration. Initial registration is very quick and can also be done when machine is stopped, reducing energy waste and material waste.

Each printing group can be moved longitudinally in a completely indipendent way thanks to the adoption of brushless motors,the results are a most accurate set point, the management of storable recipes, the reduced configuration times.

The automation platform was designed with the support of Bosch Rexroth, the industry leader in printing machine automation.

Among the novelties of S-Plus the new graphic interface, designed on 21 ", simple and intuitive but at the same time complete for the management of all machine functions

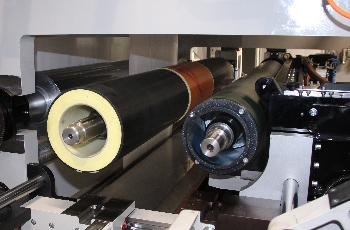

The employed technical construction solutions, and the "CANTILEVER SYSTEM" for the change of "SLEEVES" for both anilox and clichè, have allowed to reduce drastically the down-time work -changes.

- Fixed , shaft-less or turret unwinder

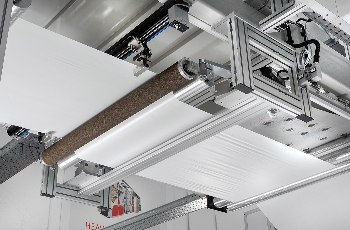

- Automatic edge guide before printing stations

- electric and / or gas drying system

- Automatic edge guide before re-winding stations

- Ink pneumatic pumps

- Viscometers system

- Videocamera for printing process control

- Chambered doctor blades with the possibility of self-alignment

- Rewinder with different winding solutions

- Material passage:

- 1050 mm

- Maximum printing width:

- 1000 mm

- Minimum printing lenght:

- 350 mm

- Maximum printing repeat lenght:

- 1200 mm

- Mechanical speed max:

- 250 m/min

- Material passage:

- 1250 mm

- Maximum printing width:

- 1200 mm

- Minimum printing lenght:

- 350 mm

- Maximum printing repeat lenght:

- 1200 mm

- Mechanical speed max:

- 250 m/min

- Material passage:

- 1450 mm

- Maximum printing width:

- 1400 mm

- Minimum printing lenght:

- 350 mm

- Maximum printing repeat lenght:

- 1200 mm

- Mechanical speed max:

- 250 m/min

- Material passage:

- 1650 mm

- Maximum printing width:

- 1600 mm

- Minimum printing lenght:

- 350 mm

- Maximum printing repeat lenght:

- 1200 mm

- Mechanical speed max:

- 250 m/min

RESERVED VIDEO:

go to the page of login or

contact us to get access

RESERVED VIDEO:

go to the page of login or

contact us to get access